- Description

Description

LARGE DIAMETER NYLON DOUBLE JACKET HOSE

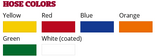

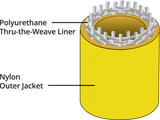

The alternative to bulky rubber LDH hose, Triple Duty is the tough, lightweight double jacket workhorse that flat out performs. Engineered for attack, supply and relay operations, its polyurethane liner is lighter than rubber and its nylon 6.6 outer jacket, treated with exclusive Dura-Cote™ abrasion resistant coating, makes this hose incredibly durable. Weighing substantially less than other LDH hose, Triple Duty is also more portable and packs tighter, requiring less hose bed space.

- Innovative. Outer jacket made from high-strength, low-stretch, filament nylon warp yarn and high tensile strength polyester filler yarn, along with a thermoplastic polyurethane liner for reduced weight and higher flow rates. Reverse twill weave of the inner jacket provides a smooth waterway and superior lining adhesion.

- Durable. Standard Dura-Cote™ protective treatment extends the life of the hose; greatly increases abrasion, heat, flame and petrochemical resistance while virtually eliminating water pick-up; also protects from mildew with no drying required.

- Flexible Hose remains flexible to temperatures as low as -40°F (-40°C) and is highly resistant to ozone and oxidation.

- Ultra-Versatile—Greater Value. Specifically engineered for attack, supply and relay operations, Triple Duty is a truly universal fire hose. Can be used for potable water in an emergency, as the polyurethane lining material meets NSF/ANSI Standard 61 for drinking water.

- Secure. Includes a lifetime guarantee against delamination.

- Certified. Manufactured in accordance with NFPA Standard 1961, latest edition within our ISO-9001 certified quality assurance system.

HOSE SIZING AND SPECIFICATION

| Size | Service Test | Proof Test | Burst | Weight (For 50′ Coupled) |

Flat Width | Bowl Size |

|---|---|---|---|---|---|---|

| IN | PSI (kPa) | PSI (kPa) | PSI (kPa) | LBS (KG) | IN | IN |

| 4″ | 300 (2070) | 600 (4140) | 900 (6200) | 46 (20.9) | 6.90″ | 4 17/32“ |

| 5″ | 300 (2070) | 600 (4140) | 900 (6200) | 59 (26.8) | 8.40″ | 5 15/32“ |

As per NFPA 1961 – The service test pressure is to be 10% greater than the “normal highest operating pressure” at which the hose is expected to be used.

.